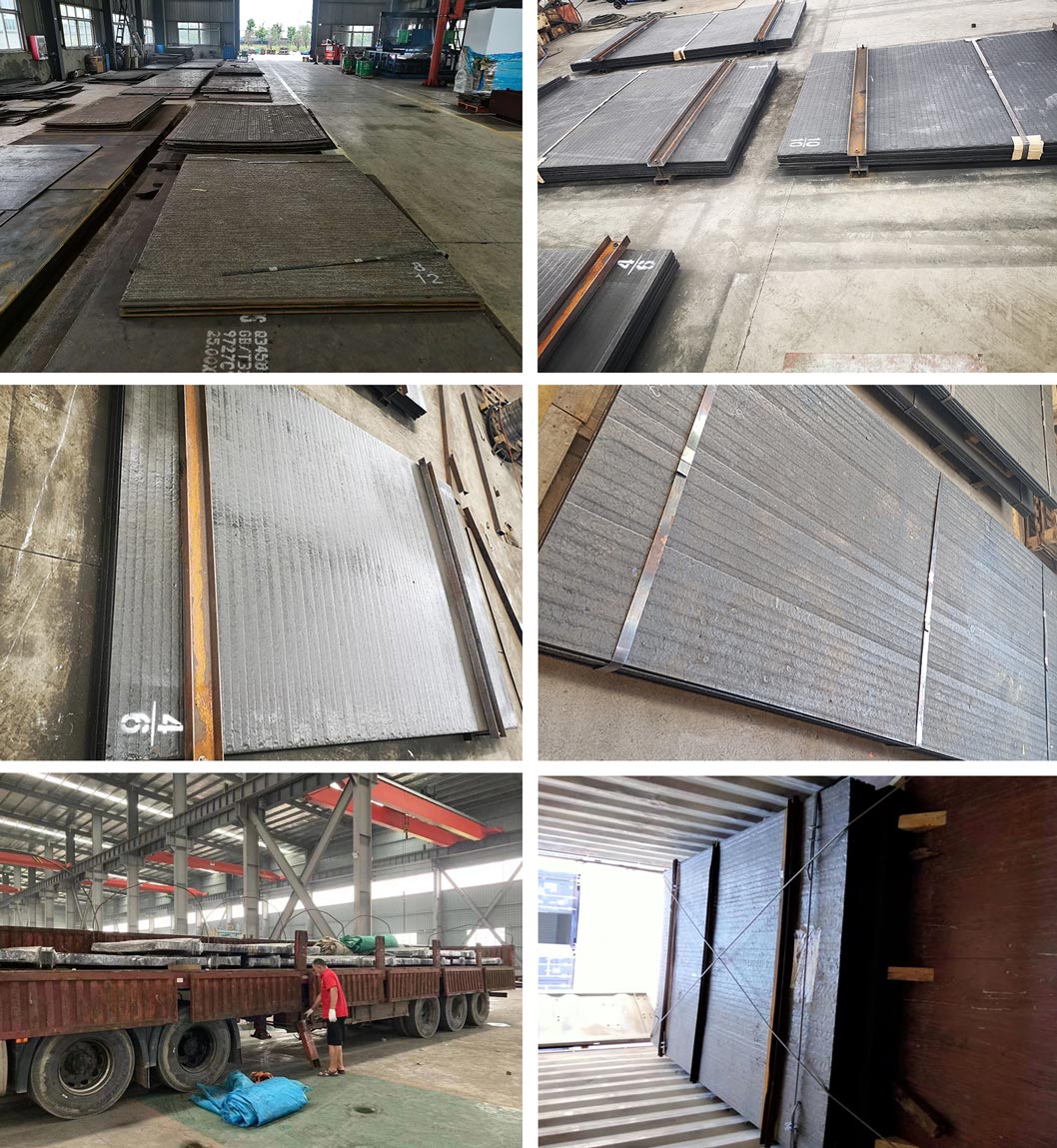

Clad Welding Wear Resistance Plates

If you are looking for a wear plate supplier to supply you with wear plates and wear steel components, then you have come to the right place. In addition to the best solutions and good service, we can also offer competitive prices for wear plates and wear steel parts.

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

VIDEO

SPECIFICATION

Get the ultimate protection for your equipment with our clad welding wear resistance plates!

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

Flux‑Cored Arc Welding (FCAW)

FCAW is the predominant method for depositing wear-resistant overlays on wear plates. This technique enables high deposition rates, which helps in building a thick and consistent hardfacing layer quickly.

Submerged‑Arc Welding (SAW)

For large plates or very thick overlay layers, SAW is often employed due to its deep penetration and high deposition efficiency. This makes it cost-effective for heavy-duty and large-scale wear-resistant plate production.

Multi‑Pass Overlay Welding

Multiple welding passes are typically used to achieve the required overlay thickness. Controlling the heat input and interpass temperature is essential to ensure a homogeneous hardfacing layer and to minimize dilution or cracking.

Stress‑Relief / Cross‑Check Cracking

As the overlay cools, a network of micro‑cracks (also known as cross‑check cracks) often forms. Contrary to being defects, these cracks help relieve internal stresses and contribute to better performance under impact or thermal cycling.

Cutting & Fabrication

After the hardfacing layer is welded, the wear plates can be cut, formed, or fabricated using common industrial methods such as plasma cutting, water‑jet cutting, or laser cutting. This customization allows wear plates to fit specific machinery geometries.

Chromium‑Carbide (Cr‑C) Alloys

Chromium‑carbide overlay is the most common material for wear plates. The Cr–C alloy forms carbide phases (such as Cr₇C₃) that provide very high hardness and excellent resistance to abrasive wear.

High‑Chromium / High‑Carbon Alloys

Alloys with elevated chromium and carbon content are used to create very hard microstructures. These materials are suited for environments with severe abrasion.

Complex Carbide Systems

For even more demanding wear applications, overlay alloys may include additional elements (e.g., niobium, vanadium, titanium) to form complex carbides. These carbides enhance resistance to erosion, sliding abrasion, and long-term wear.

Ductile Buffer or Transition Layers

To reduce brittleness and improve the toughness of the overlay, a graded or layered design can be used: a more ductile layer near the steel base plate is followed by a hard, carbide-rich surface layer. This helps balance wear resistance and impact tolerance.

Thermal Stability & High‑Temperature Alloys

For applications that involve elevated temperatures, alloy formulations can be tuned to maintain hardness at high temperatures, ensuring long-term stability of the overlay.

If the wear plate is subject to severe abrasion, then thick chromium‑carbide overlays deposited by FCAW or SAW are highly effective.

For zones with impact + abrasion, using a layered overlay (tough base + hard surface) and controlled crack patterns helps absorb shock while maintaining surface hardness.

In high-temperature environments, selecting alloy systems that retain hardness under thermal load is critical for long-lasting wear protection.

For custom parts and shapes, hardfaced plates can be pre-welded and then cut to specification, giving flexibility in design and installation.

Extended Service Life — Overlay layers with high carbide content significantly slow down wear, greatly extending the lifetime of base components.

Reduced Maintenance Costs — By using wear plates, you avoid frequent part replacement, leading to cost savings over time.

Improved Reliability — Properly designed overlays (with microstructure control and crack-relief) deliver consistent performance even under severe operating conditions.

Customization — Wear plates can be manufactured in various sizes, shapes, and grades to match specific equipment and wear profiles.

Clad welding wear resistance plates are high-performance metal plates designed to withstand extreme wear and tear in industrial and mining applications. These plates are made by welding a layer of wear-resistant material onto a base material, creating a durable and long-lasting product that can withstand harsh operating conditions.

JINHUA tungsten carbide covered wear plate, a unique chromium carbide covered plate, is located on a mild steel base. Its excellent wear resistance and abrasion resistance ensures longer equipment life while reducing maintenance costs.

Produced using a unique and versatile automated batch welding method, tungsten carbide covered wear plates are made from the highest quality raw materials and offer superior wear resistance and high durability compared to mild steel. Our fully automated production methods and quality control procedures ensure that the product has uniform chemical analysis and hardness throughout the composite layer.

The base material used is primarily carbon steel, which allows the final product to be easily welded and formed in complex structures. Other steels can be used as substrates, including stainless steel, AR and other special steels as required by the customer in specific applications.

Plates and fabrications offer excellent wear resistance and can be easily installed on all types of equipment, extending their service life while providing cost-effective protection.JINHUA's design, fabrication and manufacturing expertise ensures an increased return on your wear investment, thus giving you peace of mind.

Wear resistance plates are considered one of the most important things that manufacturing and industrial companies need. If you own one, then you have probably considered using wear plates; but what are they really for?

Many industries need to use wear plates for one or more of the machine parts they own:

Prevent excessive and premature wear

Avoid damage such as scratches, cracks, burrs, etc.

Increase or extend the life expectancy of a part

Chute liners

Bucket liners

Dump truck pallets

Feed plates

Crusher liners

Chute liners

Pipe work

Screen plates

Mobile Equipment

JINHUA can also custom manufacture wear plates to meet your specific requirements. JINHUA will help you select the right and best wear resistant products, using JINHUA developed machine made wear plates and wear resistant steel parts and help you import them from China to your plant.

If you are looking for a wear plate supplier to supply you with wear plates and wear steel components, then you have come to the right place.

Even though wear plates for wear-resistant steel are now very mature, JINHUA can always strive to make wear plates even better.

In addition to the best solutions and good service, we can also offer competitive prices for wear plates and wear steel parts.

1. Plant Introduction

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

ADVANTAGE

Superior wear quality (25 times more durable than mild steel, as verified by ASTM G65)

Uniform hardness and chemical composition

Tough austenitic matrix supporting hard carbides

Good heat resistance up to 500°C (932°F) for AB 200 and up to 600°C (1112°F) for AB 400 high temperature

Flat and smooth surface

Good integration with the backing plate, minimal penetration

Mild steel backing plate, easy to weld

Cold forming

Inner roll diameter as small as 250mm

Low dilution of alloy

Multiple sizes and thicknesses

Extremely competitive pricing

TAGS

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: