In industries that face severe abrasion and wear, finding effective solutions to protect equipment surfaces is crucial for optimal performance and longevity. Chromium carbide overlay plates have emerged as a reliable and high-performing option for combating wear and extending the lifespan of critical components.

Name: Chromium carbide overlay (CCO) wear plates

Thickness: 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12

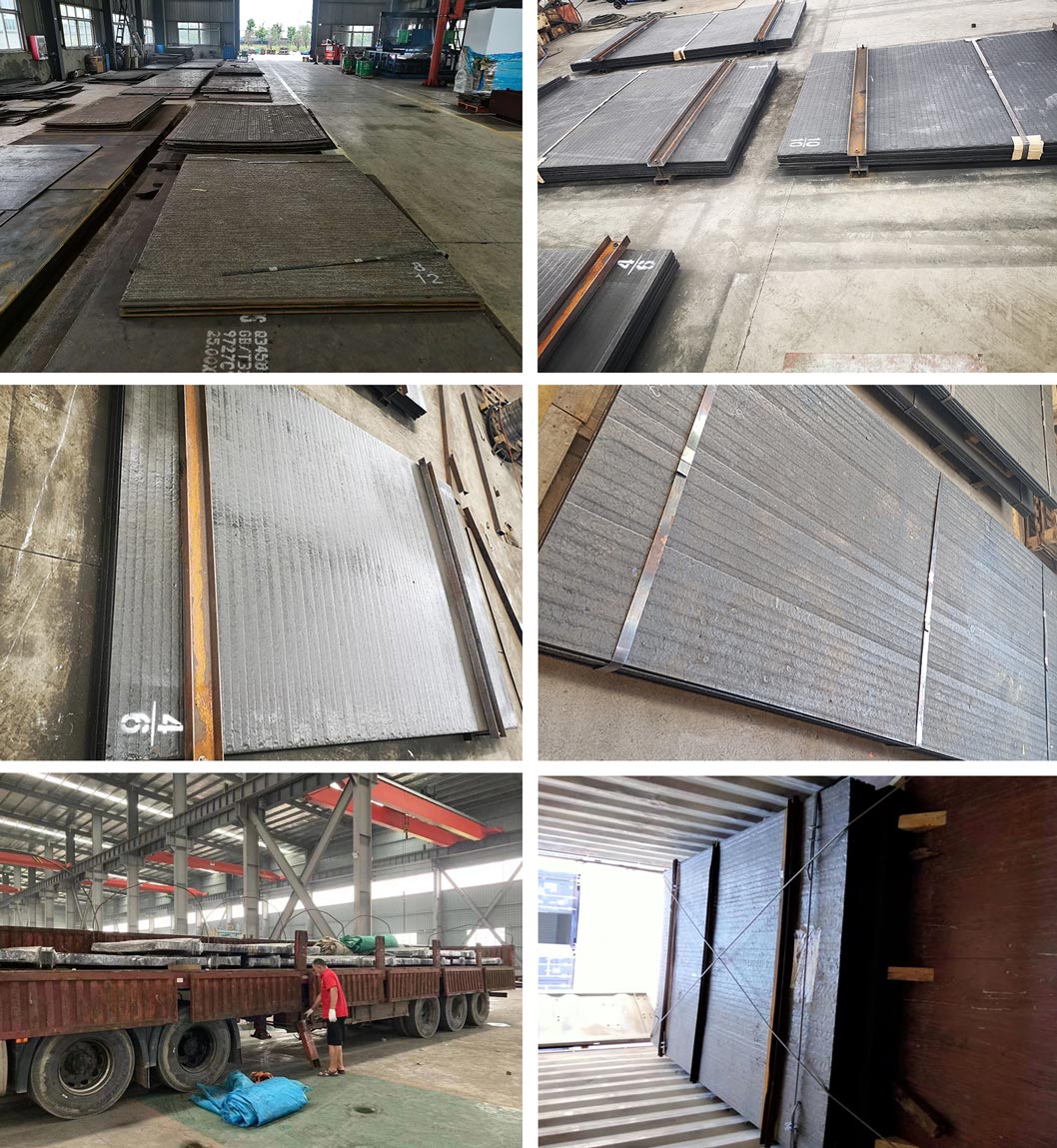

Size: 1400mm*2000mm, 1500mm*3000mm, 2000mm*3000mm and Customized Size

VIDEO

SPECIFICATION

Chromium carbide overlay, commonly known as chromium carbide wear plate, is a highly durable solution for protecting surfaces from abrasion. As one of the leading chromium carbide overlay plate suppliers, we offer high-quality CCO wear plate options for heavy-duty applications. Our hardfacing plate solutions, including chromium carbide plate, CCO plate, and overlay plate, are designed to withstand extreme wear conditions. For maximum performance, our chrome carbide plate products are engineered to deliver superior durability and resistance.

| Chemical Composition of Deposited Metal (Wt%) | ||||||

| Thickness | C | Si | Mn | P | S | Cr |

| 3+3 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-22 |

| 4+4 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 19-23 |

| 5+5 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 20-23 |

| 6+6 | 3.5-4.5 | 0.4-1.2 | 0.4-1.0 | - | - | 24-38 |

| 8+8 | 3.5-4.5 | 0.5-1.2 | 0.5-1.0 | - | - | 27-31 |

Chromium carbide overlay plates are composite materials consisting of a base metal plate fused with a layer of chromium carbide. This unique combination results in a plate with exceptional hardness, toughness, and wear resistance. The chromium carbide overlay acts as a protective barrier, significantly reducing the impact of abrasion and erosion on the underlying surface.

Flux‑Cored Arc Welding (FCAW)

The most widely used method to produce chromium‑carbide overlay plates. FCAW allows a high deposition rate, enabling a thick and dense overlay of chromium carbide on a mild steel substrate. The process ensures a strong metallurgical bond and uniform carbide distribution.

Open‑Arc Welding / Submerged‑Arc Welding (SAW)

For larger overlay plates, open‑arc or SAW methods can be employed. SAW provides deep penetration and high deposition rates, which makes it cost-effective for large-scale hardfacing.

Multi‑Pass Weld Overlay

Multiple welding passes are often used to build up sufficient thickness and ensure homogeneous carbide distribution. Proper thermal control avoids excessive dilution and potential cracking.

Controlled Crack Patterning

During deposition, micro‑cracks naturally form in the overlay layer. Properly spaced cracks help relieve internal stresses and absorb impact energy.

Fabrication & Cutting

After welding, the overlay plates can be cut, shaped, or formed by industrial processes such as plasma cutting, laser cutting, or water-jet cutting, ensuring that the wear plate can be customized for specific applications.

Chemical Composition

The overlay layer is rich in chromium (Cr) and carbon (C), forming hard chromium-carbide phases. The chemical composition typically includes 3.5–4.5% C and 24–38% Cr, depending on overlay thickness.

Carbide Phase

The dominant hard phase in the overlay is chromium carbide (Cr₇C₃), providing extremely high hardness and excellent wear resistance.

Volume Fraction of Carbides

High-performance plates often have a large volume fraction of chromium carbides (over 30%) to maximize abrasion resistance.

Hardness

Overlay hardness typically ranges between HRC 58–65, depending on the specific formulation and overlay thickness.

Base Plate Material

The substrate is usually mild or structural steel, providing structural support, toughness, and formability.

Bonding Mechanism

A strong metallurgical bond forms between the overlay and the steel substrate, ensuring the overlay does not delaminate under heavy wear or impact.

Thermal & Impact Performance

The overlay maintains high hardness even under elevated temperatures. Micro‑crack structures help absorb impact energy, reducing spalling or chipping under repeated stress.

For severe abrasion, use thick chromium‑carbide overlays with FCAW or SAW to maximize wear resistance.

For moderate impact + abrasion, controlled crack patterns and high carbide content help protect the surface without brittle failure.

For high-temperature applications, select overlay formulations that retain hardness at elevated temperatures.

For custom-shaped components, specify plate dimensions, overlay thickness, and cutting method when ordering.

Extremely high abrasion resistance, significantly extending component life.

Good impact resistance due to the combination of hard carbides and ductile steel base.

Thermal stability, maintaining hardness under high operating temperatures.

Customizable thicknesses and sizes to fit specific applications.

Cost-effective, reducing wear and maintenance intervals over the long term.

JINHUA, founded in 1996, is a global leader in the innovation and production of hardfacing wire and wear-resistant welding equipment. With over 20 years of experience, JINHUA specializes in providing complete welding automation solutions tailored to various industries, including mining, agriculture, recycling, and construction. Partnering with TELF AG and utilizing top-grade FeCrHC from Kazakhstan, JINHUA delivers superior quality hardfacing consumables. Certified to ISO 9001 standards, JINHUA is committed to offering reliable, high-quality products that exceed industry expectations across sectors such as petroleum, automotive, and aerospace.

When it comes to safeguarding critical equipment surfaces from abrasion and wear, chromium carbide overlay plates offer an effective and durable solution. Their exceptional wear resistance, versatility, and customizability make them an ideal choice for various industries. By investing in high-quality chrome carbide overlay plates, businesses can enhance equipment lifespan, reduce maintenance costs, and improve overall operational efficiency. Choose our reliable solutions to optimize the performance and durability of your equipment. Contact us today at to explore our range of chromium carbide overlay plates and find the perfect fit for your specific needs.

ADVANTAGE

Jinhua's chromium carbide composite steel plates offer outstanding strength and corrosion resistance. This bi-metallic product begins with a mild steel base plate, which is then fused to the chromium carbide steel by welding. With up to 32% chromium (Cr) and up to 5.8% carbon, chromium carbide metallurgy is bonded to the surface of the steel, creating a protective and durable surface that will not separate from the base metal.

Chrome carbide overlay steel is extremely hard, both wear and impact resistant, and can withstand high temperatures. As a result, Jinhua's composite plates are ideal for extreme wear applications, high temperature environments and where corrosion is a problem. The chrome carbide overlay coating also provides a high level of impact resistance.

On average, 4 to 6 times longer life than AR steel

Fast return on investment

Excellent resistance to chipping, spalling and separation

Abrasion resistance up to 1,250º F

Available in a variety of thickness combinations

Maximum wear resistance

Multiple grades

Made in China, cost effective

Cost-effective solution compared to conventional wear-resistant steels

Recommended for resistance to wear, micro-movement, cavitation and particle erosion in high temperature applications (up to 1100°F)

Suitable for mild to moderate impact wear resistance

Low maintenance and easy to install.

The cover of the CCO plate will consist of a series of beads with numerous fine line cracks. These properly spaced cross-check cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

We have equipped with our own developed wear plate hardfacing machine, including single torch, double torch and quadrule torch wear plate hardfacing machine, total 25 uints hardfacing machine.

Jinhua is able to experiment and effectively manufacture chromium carbide overlay (CCO) wear plates using open arc welding with advanced fusion welding technology.

As a result, Jinhua is able to apply highly wear-resistant chromium carbide to steel substrates. In addition, our team is able to produce consistent microstructures and chemicals at the edges.

Jinhua's Chrome Carbide Overlay wear plates are a unique Chrome Carbide overlay on a mild steel substrate designed for areas with severe impact and wear.Jinhua can form, roll and cut to your specific needs.

TAGS

Copyright © Jinhua (Qingdao) Hardfacing Technology Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: